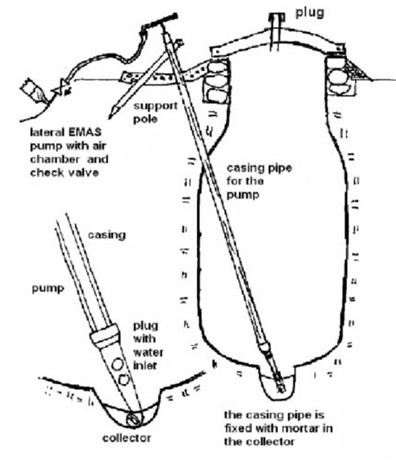

In the past the Breurram has been built and tested by the WOT. It is a type of hydraulic ram pump, made out of standard components using an airbuble in a piece of flexible tube as expansion ‘tank’.

More about the mechanism behind the Breurram can be found in this youtube video.

Several times the WOT has been asked: What would happen if you scale up the Breurram?

Our earlier demonstration and test set-up uses 1” valves. Following yet another advice request and subsequent visit at the WOT, we decided to test a larger version of our beloved ram pump.

The diameter of the Breurram can, according to the manual, not be larger than it’s supply line.

Because the supply of water from our ferrocement tank/cistern to our testing rig ends in a 2” pipe, a 2” Breurram has been constructed. Only the valves have been purchased, as other materials were present. The cost for these came down to about €95.

Upon first testing it became apparent that the system wouldn’t work reliably without the optional

tensioning spring. Next to this problems were found with starting the pump. Therefore a bracket has been placed on the spill valve connected to a bolt sticking out of the pump, allowing the valve to be moved manually at start up. Depending on the setting of the tensioning spring and the pump head the system was able to work without human intervention. The frequency of the pump cycle was far less constant compared to our other, smaller, Breurram. What this is a result of remains a question at this point, but suggested are lower flow speeds and/or quality of components.

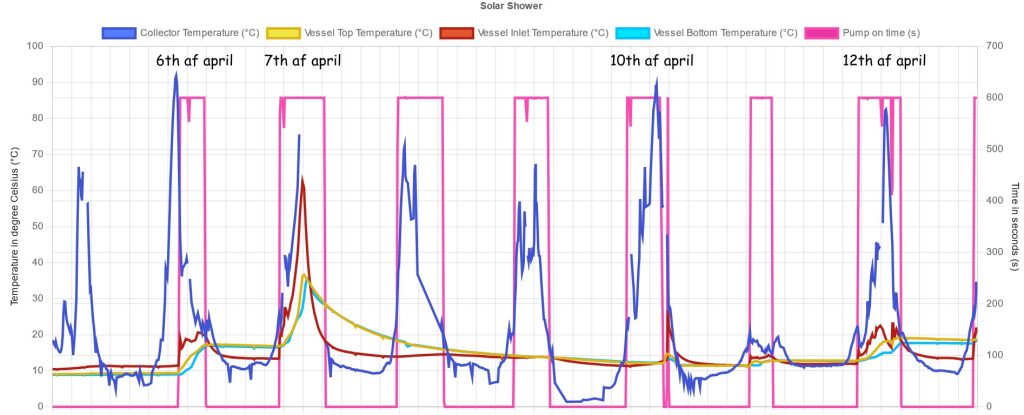

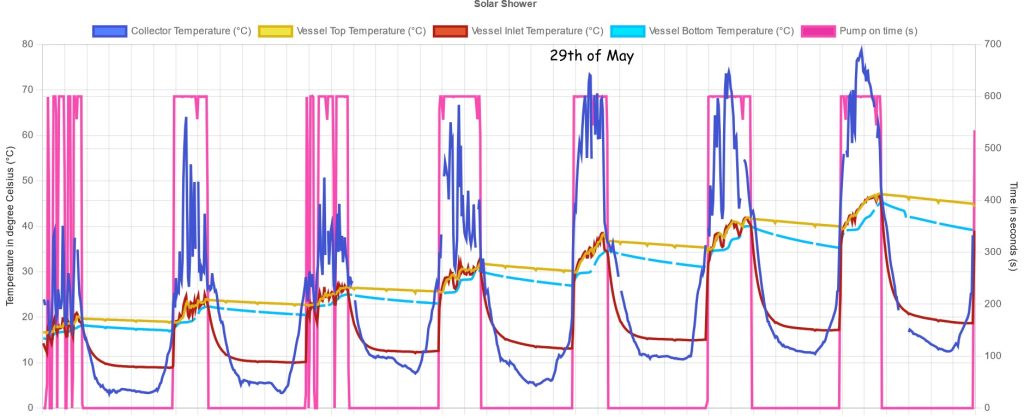

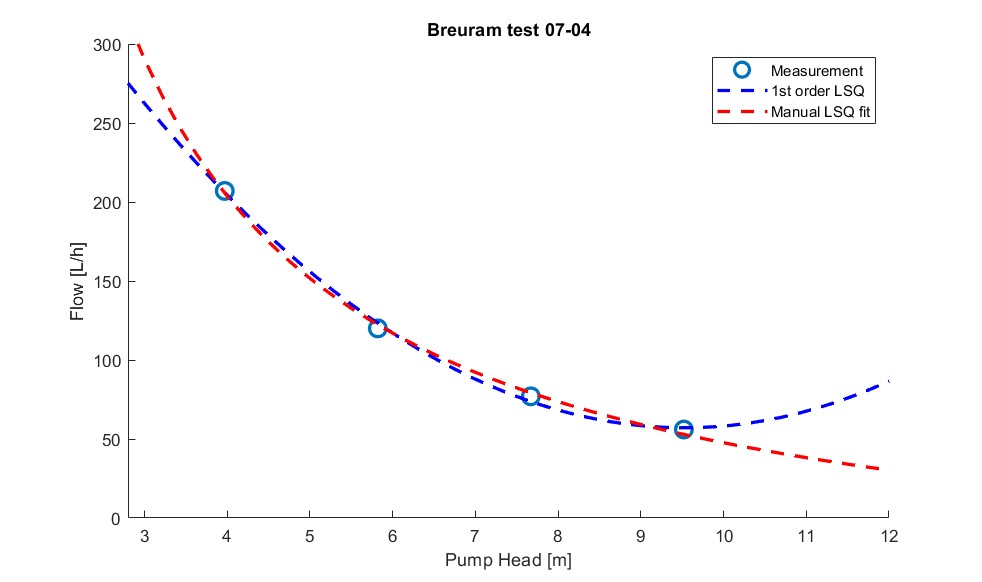

Tests are done using a supply head of 184 cm (approximately) and pump heads of 397, 582, 767

and 952 cm. Using a return line and a petrol pump pumping back used water to the supply tank, the supply head was held as constant as possible. So far one test has been completed at a constant

setting of the tensioning spring. The yields at different pump heads and several curvefits can be seen in the following figures, as well as some picutures /visualisations of the test/setup.

So far, in order to draw more accurate conclusions several more tests will be conducted, of which the results can be expected in the near future. This will also include a (rough) comparison with the yields of our other, smaller, Breurram. You can read more about hydraulic rams here.